What is Biomass?

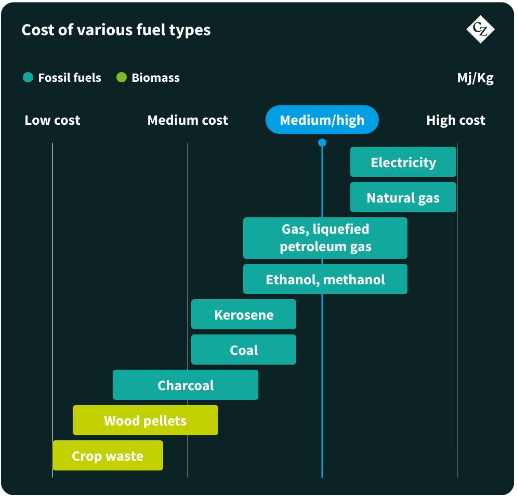

Biomass is a fuel derived from organic material such as agricultural and plant residues (e.g., wheat straw, rice husk, sugarcane bagasse), wood and forestry residues (e.g., woodchips, sawdust, wood pellets), and municipal waste.

Agricultural and forestry residues, also knowThe Netherlandsn as biomass feedstock, are commonly used to generate bio-energy. Bioenergy is a term used to describe energy derived from biological and organic materials, such as forestry or agricultural waste.

How is Biomass converted into Energy?

Torrefaction is the most common method for converting biomass into energy, but other methods include pyrolysis and gasification.

Torrefaction

Torrefaction, also known as Thermal Conversion, is the process of dehydrating and stabilising biomass feedstock before burning it to generate energy. Torrefaction involves applying heat to wet/hydrated biomass at temperatures ranging from 200°C to 300°C, causing it to lose its ability to absorb moisture and transforming it into a dry, darkened substance that is compressed to form Briquettes.

Briquettes are a type of wood fuel made from compressed combustible material.

Briquettes are then converted into energy through direct combustion, in which the steam produced during the burning process powers a turbine, which drives a generator to produce electricity. Briquettes can be easily stored in moist environments, making them popular and convenient energy sources.

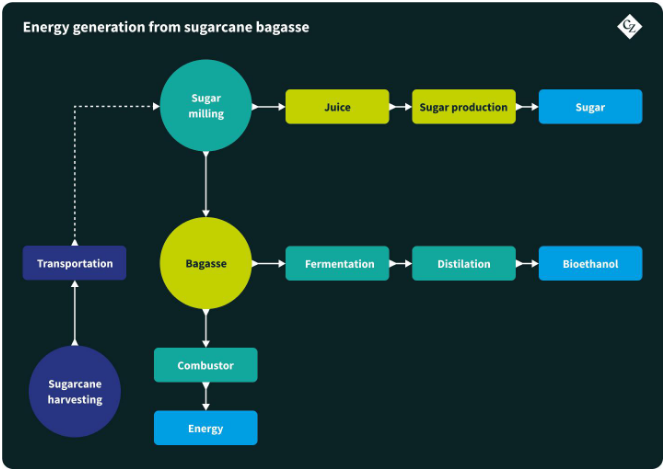

Sugarcane bagasse is one example of agricultural waste that can be converted into energy through torrefaction. Once sugarcane is taken to the mill, it goes through the crushing process for sugar to be extracted. After sugar is extracted from cane, the waste left is called bagasse which is burned in order to power the mill.

Although torrefaction is the most widely used process, pyrolysis and gasification are also viable options for converting biomass into energy.

Pyrolysis

Pyrolysis is the process of heating organic material to 400° C – 500° C in the absence of free oxygen. Biomass pyrolysis generates fuels such as charcoal, bio-oil, renewable diesel, methane, and hydrogen.

Gasification

Gasification is the process of heating biomass feedstock to around 800° C – 900° C with a controlled amount of oxygen, causing the molecules to break down and produce syngas (synthesis gas). Syngas can also be converted into transportation biofuels and fertilisers, and it can be burned or used in fuel cells if treated to separate the hydrogen from the gas.

Forestry Biomass

Forestry is a key biomass-producing sector that provides valuable energy sources to the EU. In regions with abundant feedstock, such as Germany, Sweden, and Latvia, the use of forest biomass as a fuel for electrical power generation is growing.

Germany is the largest importer of hazardous wood waste and serves as a sink for Europe’s hazardous wood waste. According to the International Energy Agency (IEA), the lack of capacity for handling wood

waste, combined with the constant need for feedstock, can have an impact on the trade of hazardous wood waste. For example, the Netherlands lacks the legislation and capacity to deal with hazardous wood waste, so it is primarily exported to Germany for disposal (IEA, 2018).

There are many nations where it is more expensive to dispose of waste than to trade it; in the Netherlands, Germany, and Sweden, there is a tax on landfilling waste. This landfill tax also includes the disposal of hazardous (chemically treated wood) and non-hazardous wood waste. Occasionally, depending on the waste being disposed of landfilling is outright forbidden. These financial constraints, according to the IEA, force the shipment of hazardous wood waste across borders.

EU Landfill Tax

Sweden

Landfill Tax in €/Tonne: 540 SEK/t = €51/t

Landfill Tax Plan: Adjusted yearly

Landfill restrictions implemented:

- Since 2002, no sorted combustible waste.

- Since 2005, no organic waste.

The Netherlands

Landfill Tax in in €/Tonne: 33.15 €/t

Landfill Tax Plan: Adjusted yearly

United Kingdom

Landfill Tax in in €/Tonne: Rates from 1st April 2022 to 31st March 2023:

- £98.60/t (standard rate)

- £3.15/t (lower rate)

Landfill Tax Plan: The rates are adjusted annually for inflation and cannot fall below £80/t until 2020.

Source: Confederation of European Waste-to Energy Plants

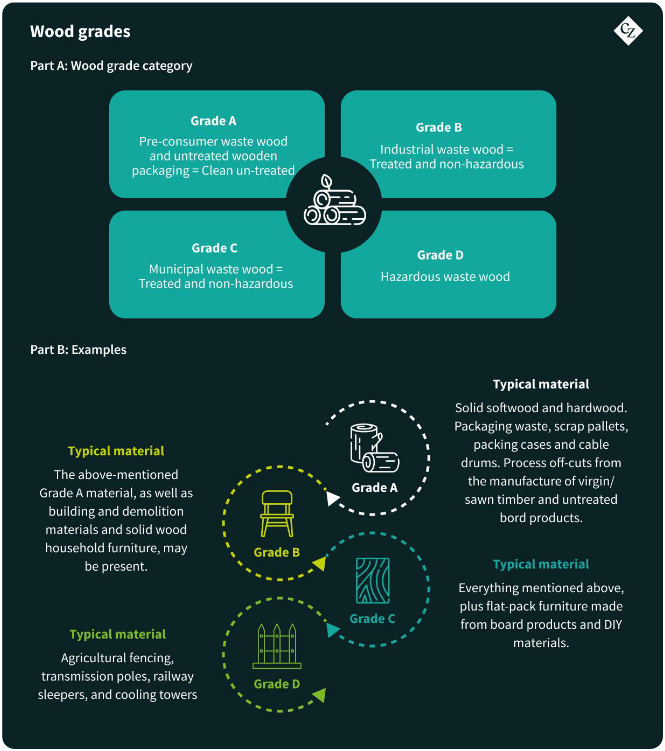

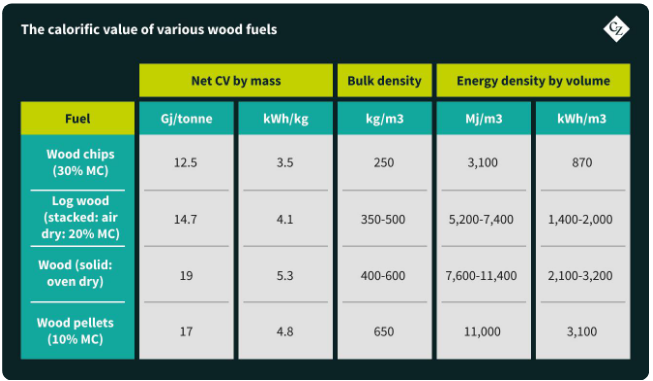

Wood chips are available in a variety of grades. Recycled A grade woodchip is favourable because it has a higher calorific value than virgin woodchip and is less expensive per tonne.

Wood Grades

According to the IEA, the key driver for both hazardous and non-hazardous wood waste utilisation is legislation and policies, which vary across EU countries. The assistance provided by a country’s legislation and policies can pave the way for improved capacity to deal with hazardous and non-hazardous wood waste.

In addition, due to the adoption of a comprehensive waste management legislation in 1990, Germany is one of the major importers of wood waste, importing grades A, B, and C. Sweden, the second-largest net importer of wood waste, importing both hazardous and non-hazardous wood waste.

More Information regarding wood grades can be found below:

Source: The Wood Recyclers’ Association

According to Perpetual Energy Ltd (an energy company that develops renewable heat and power systems), the moisture content of wood chip is critical. If the moisture content is too high, a boiler may shut down or provide a low calorific burn value per tonne of wood. Furthermore, if the temperature is too low and the wood chip is too dry, it will burn too quickly. So therefore, one of the most important factors influencing the operation of a biomass boiler is a consistent supply of high-quality wood chip with the proper moisture content.

Source: The Engineering Toolbox; Brookings

Source: Our World in Data

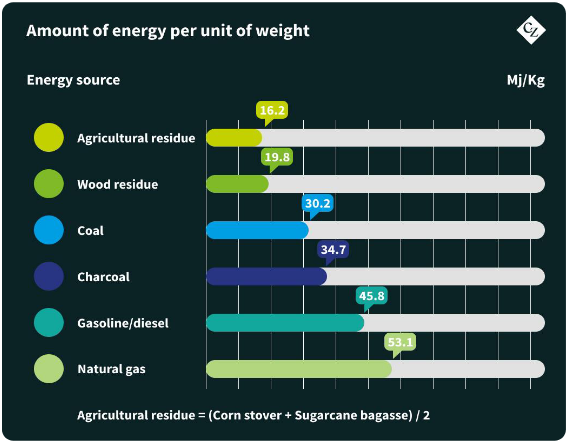

Calorific Energy

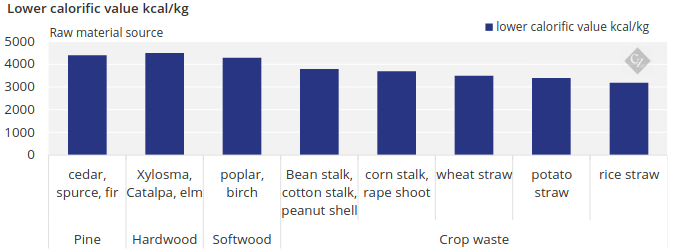

In the context of bioenergy, the energy produced from biomass feedstock is measured using the calorific energy value (KJ/Kg). The heat of combustion, also known as the Calorific Energy value, is a standard unit of measurement for the total energy content produced in the form of heat when a substance is completely combusted with air/oxygen.

The net calorific value is significant because it represents the practical energy remaining after burning the biomass.

Source: Gemco Energy

The calorific energy produced by wood pellets and wood chips varies depending on the type of wood grade and is an indicator of their quality.

Source: Forest Research

Sustainability

Biomass energy, like wind and solar energy, is a widely available renewable energy source that can help reduce our reliance on fossil fuels and reduce our carbon footprint. However, if biomass feedstocks are not renewed as soon as they are consumed, they can become non-renewable. For example, cutting down trees for use as biomass feedstock may result in deforestation if the trees are not replaced.

Furthermore, there is a widespread misconception about the long-term viability of using biomass to generate heat and electricity. It is commonly assumed that because trees and plants remove carbon dioxide from the atmosphere during photosynthesis, burning them for energy should balance it out. However, it is not as simple because plants and trees require time to regrow and recover. As a result, if trees and plants are burned faster than they are replanted, biomass energy is no longer sustainable.

Most countries share these sustainability concerns and have either implemented or are in the process of implementing laws and policies to ensure that biomass feedstock is produced in a sustainable manner. For example, the UK, as well as most EU countries, require evidence of sustainability certification compliance (as well as auditing skills).

Depending on the type of biomass, various certifications are available; for forestry biomass, there is the:

– Sustainable Forest Initiative

– Forest Stewardship Council

– Programme for the Endorsement of Forest Certification

Agriculture-based biomass is a relatively new source of energy than forestry/woody biomass, so there are fewer regulations or certifications in place. Nonetheless, as agricultural biomass expands and becomes a significant source of renewable energy, there will be certifications and regulations in place governing the sustainable sourcing of agricultural waste and trade flows.