Freight Course Overview

Welcome to Czapp’s course on freight. We hope it helps you understand how goods move around the world.

The course is split into 6 articles, with a special focus on ocean freight and less emphasis on road, rail or air freight:

1) Types of Freight

2) Drybulk Ocean Freight: Who Does What?

3) Drybulk Vessels, Cargoes and Routes

4) Drybulk Freight Contracts

5) Freight Costs and Price Risk Management

6) Container Freight

We understand that moving things can be quite a dry topic, best enjoyed by supply chain nerds. We aim to bring it to life so that one day you might become a supply chain nerd too. Please send us your feedback to help us improve future editions of this course.

Freight Basics

Imagine you wish to move something over a long distance.

Perhaps you operate a beverage factory and need bottles to package your products. Or perhaps you make the bottles and have sold them to the beverage factory and need to fulfil your contract with them. It’s helpful to know what options are available to you and what terminology you may need to be familiar with.

“Cargo” and “freight” are often used interchangeably. But technically there’s a difference. “Cargo” refers to goods being carried and “freight” refers to the act of carrying the cargo.

Cargo can be packed in different ways. The most common are bulk, breakbulk, container and tanker.

Cargo can also be transported in different ways: road, rail, air, barge and ocean.

In a single supply chain several different packing formats and transport modes may be used.

In a single supply chain several different packing formats and transport modes may be used. In general, the fewer packing changes and modes of transport used the lower the cost as you eliminate double-handling.

However, optimising a supply chain so that only one packing format or transport mode is used might lead to other avoidable costs. For example, operating a fully containerised supply chain was optimal in 2019, but sub-optimal in 2021 when covid lockdowns and container shortages led to delays on some routes. Experts at Czarnikow can help provide the best supply chain performance at the lowest cost.

In this course we will look mainly at supply chains moving dry goods across borders. This means we will concentrate on ocean bulk, breakbulk and container movements. A brief history of ocean freight should help you understand services and trends today.

History of Freight

For most of human history, break-bulk items were loaded, lashed, unlashed and unloaded from the ship one piece at a time.

This required a large labour pool of skilled and unskilled stevedores to move cargo from port warehouses to quayside, carry the goods onto the vessel, load the vessel holds safely and lash the cargo in place. The whole process was then reversed for unloading.

Source: Shutterstock

To reduce costs of onward movement of goods and to ensure a large pool of stevedore labour, major ports were mostly located within towns and cities, and had miles of piers for mooring and loading/unloading vessels. By way of illustration, in 1900 the world’s 3 largest ports were London, New York and Liverpool.

Source: Wikipedia

The world’s ports changed beyond recognition following the uptake of the intermodal container in the latter half of the 1900s. Cargo was grouped and packed once into standard containers. These containers were then loaded and unloaded onto ships, trucks, rail or barge by crane. When a ship’s hull was fully loaded, additional containers were stacked and secured on top.

Source: Shutterstock

As a result, gangs of stevedores were no longer required. Vessel loading and unloading times accelerated. Today it can take less than a minute to load or unload a container from a vessel. This means an entire ship can be loaded or unloaded in a few hours, not the several days required before containerisation. This has helped to greatly reduce shipping times as less time is spent in port. It now takes weeks rather than months for a consignment to arrive in Europe from East Asia.

With stevedores largely not required, port facilities also changed. Inner city shorefront warehousing and piers were unnecessary. Ports instead needed deep berths, room for cranes and vast lots to store and sort containers. As a result, London and Liverpool ports declined, being partly replaced by container facilities at Felixstowe and Southampton. Manhattan’s port activity was replaced by New Jersey.

The job of packing and sorting cargoes also didn’t need to be done on the quayside, and so this work moved to warehouses away from major ports but close to in-country hubs. With containers pre-sorted and packed before arriving at port, there has also been less breakage due to less frequent handling and reduced cargo theft.

Today, most packed cargo is shipped using containers. Almost all industrial raw materials like coal, iron ore and grains are shipped in bulk.

Freight Routes: Liner and Tramp

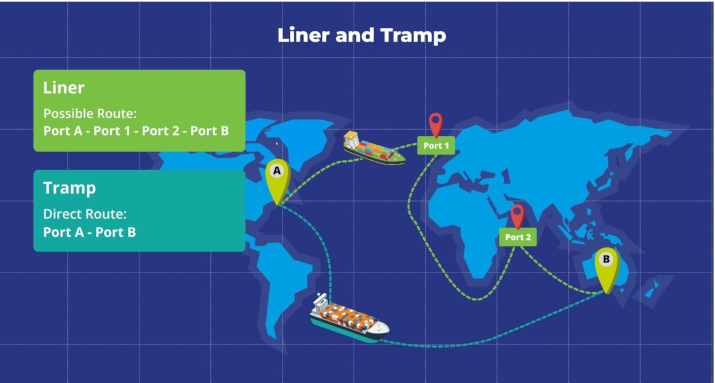

As well as dividing shipping by the way it’s carried, we can also distinguish between the way the ships themselves operate their routes. There are two major classes: Liner and Tramp.

Liner business is when vessels operate according to a published tariff and schedule of ports. Cargo can be booked for shipment between these ports with shipping lines. Most container shipping is liner business.

Tramp business is where owners or operators offer their vessels for hire to carry cargoes between any suitable ports in the world, according to a bespoke contract called a charter party. Most bulk shipping is tramp business.

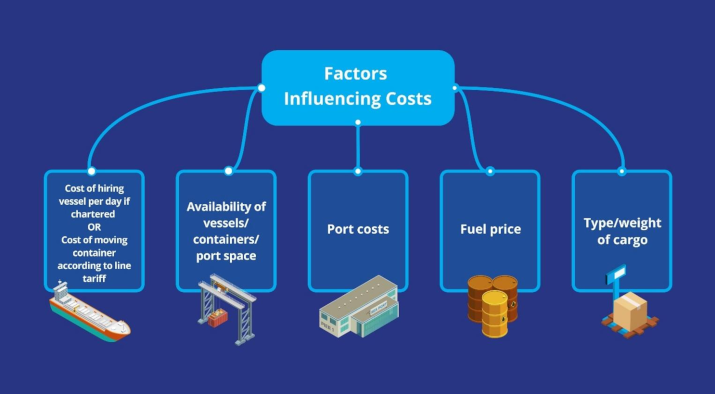

Factors Influencing Costs

Later in this course we will examine ways that you can reduce freight costs, or at least mitigate the risk that freight costs increase. Here are some of the factors which determine how much it costs to move goods around the world by ship.