Insight Focus

Fischer-Tropsch and HEFA lead current SAF production globally. Other pathways are less developed and unlikely to scale by 2030. Their dominance stems from mature technology and widely available feedstocks.

Sustainable Aviation Fuel (SAF) refers to non-conventional aviation fuels made from renewable or waste-derived feedstocks. SAF is a critical component of the aviation industry’s strategy to reduce carbon emissions, as it can significantly lower lifecycle greenhouse gas emissions compared to conventional jet fuel.

One way to produce SAF is through Synthetic Blending Components (SBCs), which are created via specific processing methods using various feedstocks such as vegetable oils, waste fats, agricultural residues or even captured carbon dioxide. These SBCs are then certified under technical specifications like ASTM D7566, which outlines approved “annexes” or production pathways.

While we have scrutinised the technical pathways—feedstocks and processing methods that give rise to SBCs—we have not yet considered the current and near-future state of play regarding scale and availability. We will consider these now.

Early Pathways Dominate SBC Market

At present, the most mature pathways for SBCs are the first two annexes in D7566: The Fischer-Tropsch (FT) process (Annex A1) and the Hydro-processed Esters and Fatty Acids (HEFA) process (Annex A2).

The others are much further behind and represent only a tiny fraction of the volume produced by the first two annexes. While many show real promise, they are all behind on the development curve and are highly unlikely to contribute significantly to the aviation sustainability targets of 2030.

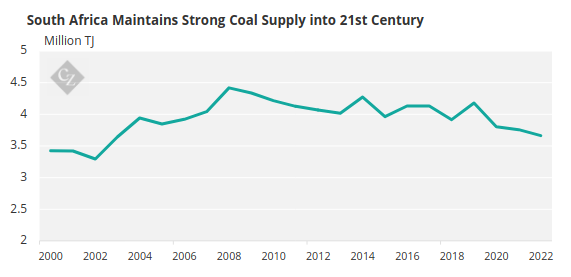

This balance of availability can be easily explained. First, the earlier annexes are more mature and therefore have had more time to scale up—particularly the FT process (A1), which has existed for about a century and has been utilised in South Africa, where liquid fuels have been produced from coal for decades.

This is largely because South Africa is rich in coal but not crude oil, and the political isolation before 1994 drove the need for fuel security towards coal and FT. (Note, however, that using coal as an FT feedstock means any jet fuel produced offers no sustainability benefit.)

Source: IEA

Secondly, from a thermodynamic perspective, the HEFA process (A2) uses an energy-rich feedstock: vegetable oil. This is essentially a hydrocarbon, very similar to the SBC required, but with a small amount of oxygen embedded in its structure. Oxygen is not permitted in jet fuel components, so the processing is straightforward: knock off the oxygen, then crack the resulting intermediate hydrocarbon and reform to get it to the right size.

Here lies a technical dilemma between SBC and renewable diesel (RD): the intermediate hydrocarbon is too large for SBC but ideal for RD. As a result, RD is simpler to produce via HEFA and therefore technically more attractive. Of course, other factors also come into play, such as the relative market value of SBC versus RD and the level of demand. Nevertheless, HEFA is a good starting point for SBC production—and an even better one for RD.

Overall…

At present, Annexes A1 and A2 produce the bulk of synthetic and sustainable jet fuel, thanks to the maturity of the process technologies, the widespread availability of feedstocks and the relatively high energy content of the feedstocks.

Other, perhaps less significant, factors include the ease of transporting feedstock. For instance, vegetable oil, being an energy-dense liquid, is easy to distribute. As a result, getting it to the processing plant is less challenging and less carbon-intensive than, for example, collecting agricultural waste from fields or extracting CO₂ from the atmosphere.

Next time, we’ll explore the remaining annexes and the headwinds they face.