Insight Focus

PET recycling faces critical challenges with quality and availability. Mechanical recycling is a leading method but there are issues with contamination and quality. Chemical recycling is growing, but the sector is challenged by energy costs as targets and mandates push for faster solutions.

It won’t surprise you to know that PET recycling is at a critical point. With inconsistent collection systems, contamination issues and the limited availability of high-quality recycled content—especially food grade—the need for reliable recycling is greater than ever. Regulatory demands are ratcheting up at the same time as brand-level sustainability targets are accelerating demand for rPET.

A positive response to this availability challenge is the exciting innovation in mechanical and chemical recycling technologies. The push toward a circular PET economy is reshaping value chains and requiring unprecedented collaboration across sectors, particularly with regard to PET converters.

So, what are the main types of PET recycling, and what’s the latest progress?

Mechanical Recycling Leads

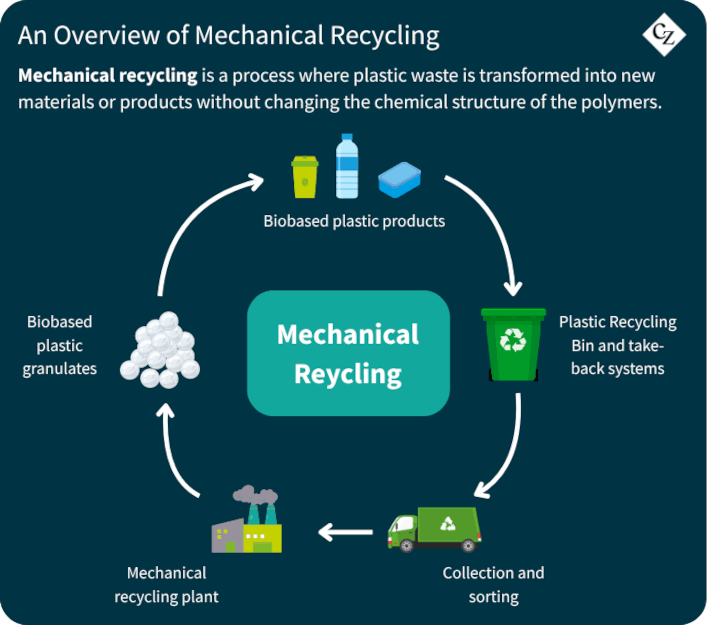

The most common method of PET recycling currently, mechanical recycling involves sorting, washing, shredding and remelting plastic without changing its chemical structure. PET and HDPE are already widely mechanically recycled across Europe and the US, making it accessible, but challenges include limitations in achieving clean, single-polymer streams.

There’s also the medium- to long-term issue of quality degradation after repeated cycles, as well as the problem of potential unsuitability for food-grade applications.

Chemical Recycling Continues Growth

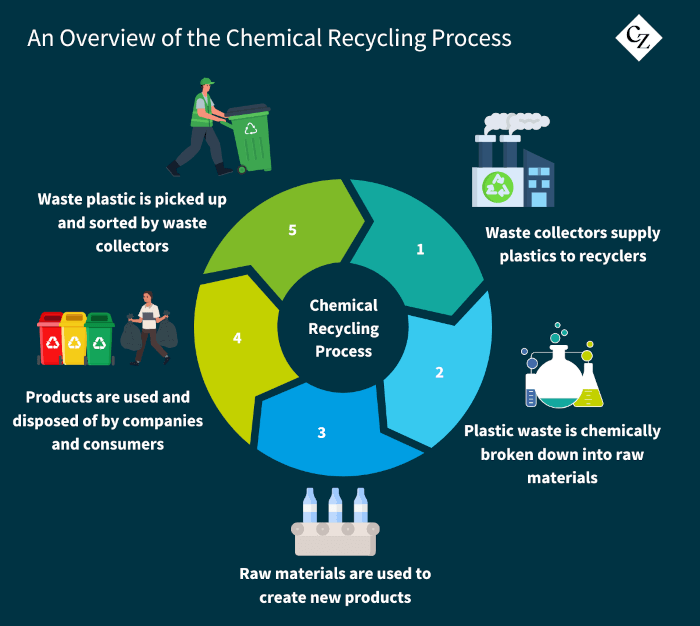

The depolymerisation of PET is the chemical recycling process, which is currently less available but certainly growing in popularity and accessibility, with various early-stage plants in Europe and the US.

The technical part is that chemical recycling breaks down PET into monomers, which are then repolymerised into virgin-quality PET. The tricky part is that this process consumes a lot of energy and requires highly complex technology, so the initial capital costs are high.

Other Technologies Face Hurdles

While mechanical and chemical recycling are by far the two leading technologies, there are a few other options that have their fans—and their detractors.

Solvent-based recycling, also known as ‘dissolution’, is currently available in Europe on a limited commercial basis. This process dissolves polymers using solvents without breaking molecular chains, which is handy. As you can imagine, it requires significant chemical expertise for handling and purification, so it’s expensive and, consequently, not widely adopted.

Pyrolysis is steadily increasing in popularity for polyolefins like LDPE and PP, but it’s not yet suitable for PET, due to issues with feedstock consistency, emissions and the purity of the end product. This process converts mixed plastic waste into fuel or feedstock through thermal decomposition. There is some investment in pyrolysis in the US, but it’s largely unheard of in Europe for commercial applications.

Perhaps the most experimental option is enzymatic recycling, which uses enzymes to break down polymers—including PET—into monomers at low temperatures. There are some R&D and pilot projects in Europe, but scalability, required investment and uncertainty about how these enzymes perform are still being worked out.

For PET converters, these evolving technologies and their various pros and cons mean adapting to more complex rPET streams, investing in certification and traceability and staying aligned with both legislative requirements and the sustainability goals of stakeholders.