Opinion Focus

- Staffing shortages have plagued the supply chain since the COVID pandemic struck in 2020.

- Now, as strike activity ramps up, companies are looking to mitigate staffing-related disruptions with automation.

- The profile of the future workforce will change dramatically to keep pace with this innovation.

Automation and advanced technologies are here to stay in every stage of the supply chain. Although this can generate efficiencies, there is a concern that large scale adoption will jeopardise jobs, especially as worker discontent continues to rise. But robots can actually create more jobs for humans… it’s just a question of a changing skillset.

Robots Streamline Production Processes

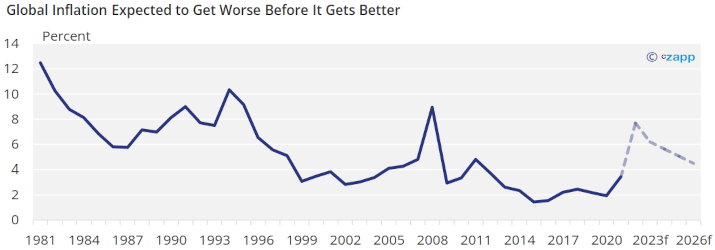

For the past year, the world has been battling with high levels of inflation.

Source: World Bank, IFO Institute

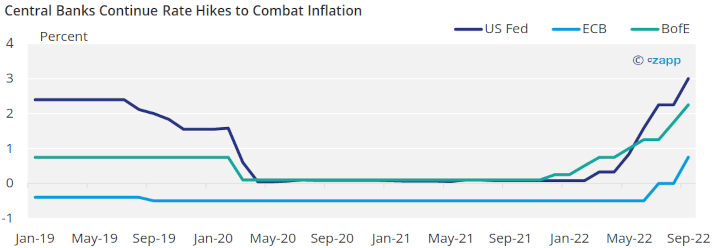

Too much money in the economy and demand that outstrips supply have fuelled this inflation and prompted central banks to raise interest rates. This in turn results in a more expens ive cost of living. And doing business.

Source: US Fed, European Central Bank, Bank of England

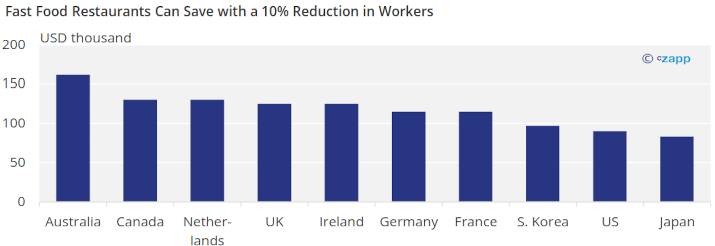

In an environment of high wages, the initial investment of a robot can make sense.

Source: FT

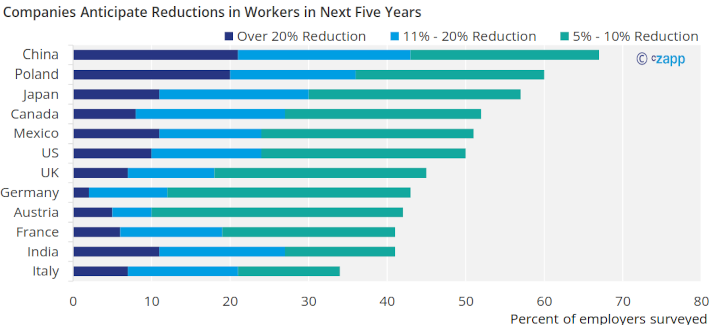

And many companies do anticipate reducing in their employee numbers in the coming years.

Source: Boston Consulting Group

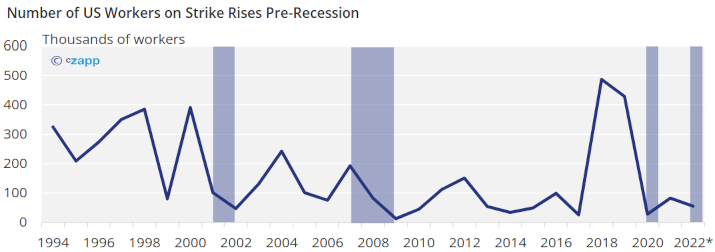

Wage growth stagnation and rises in the cost of living generate greater global unrest among workers. Strike activity tends to pick up before a recession, as has been the pattern in the US since the early 2000s.

Note: Shaded area represents recession

Source: US Bureau of Labor Statistics

Amid global supply chain snarls and rising costs, labour costs are sure to rise too. All this means the global supply chain has faced unprecedented challenges, with even more to come.

Procurement Challenges Retailers

Even in a normal scenario, retail procurement is particularly difficult because seasonality plays a huge role in sourcing, especially for those in the food trade.

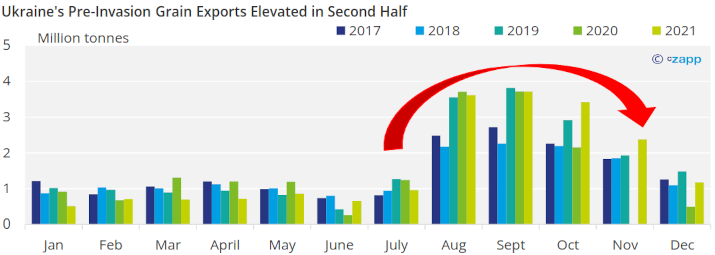

For example, in the last quarter of the year in much of the western world, more stock is needed than in the first quarter due to higher sales during busy holiday periods. And prior to the invasion of Ukraine, the Black Sea was congested with vessels trading grain from July to November, impacting freight supply and demand dynamics.

Source: UN Comtrade

While these events can be relatively easily predicted, others are slightly more difficult. And moving too early or too late could risk high warehousing costs, higher costs of goods or it could cost companies millions of dollars in sales.

AI Can Predict Supply Timelines

The good news is that there are plenty of AI solutions coming onto the market that can help companies manage inventories. With AI, the process of inventory ordering can be automated when stocks run low. If the technology is equipped with additional data such as freight traffic flows, it can choose the optimal time to place an order.

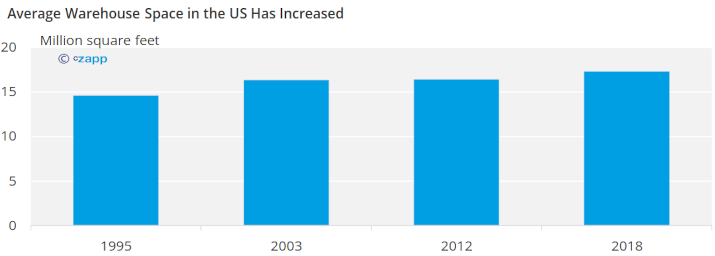

This can be complemented by drone technology that can count stockpiles and inventories, replacing manual inspections and ultimately automating the replenishment process. This is especially important as warehouse sizes get bigger and bigger.

Source: US Energy Information Agency CBECS Survey

This is especially pertinent as companies move away from just in time logistics and hold more stock in warehouses, implying extra costs. Stock management technology can make a big impact on the bottom line by creating efficiencies.

AI technology evolves as more data is added. Nowadays, companies have access to huge swathes of consumer data, from government tracking data, Google search insights and even information from survey companies such as Kantar or Nielsen to tell them what consumers like to buy and when. Retailers and even freight forwarders with the right information can create targeted offers that anticipate client needs.

It is even possible to understand what consumers want even if they don’t. Danish firm iMotions offers neuromarketing technology that tracks the path of the consumer’s eye, as well as conducting real-time facial analysis to understand their opinion of a product.

Tech Provides Greater Transparency, Accuracy

Importantly, AI can also automate manual data entry, minimising human error, saving time, and increasing productivity.

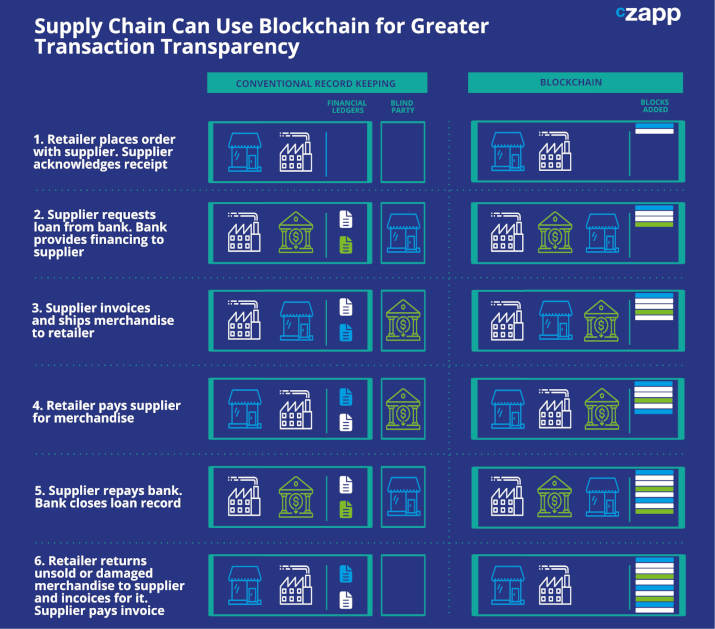

Not only this, but other technologies such as blockchain can provide an important layer of transparency to make supply chains more and more responsible – without requiring costly and time-consuming audit measures. Blockchain is essentially able to capture many more details than a conventional transaction and each block is encrypted to ensure it is tamper-proof.

According to an article published in Harvard Business Review, “since participants have their own individual copies of th e blockchain, each party can review the status of a transaction, identify errors, and hold counterparties responsible for their actions. No participant can overwrite past data because doing so would entail having to rewrite all subsequent blocks on all shared copies of the blockchain.”

Blockchain implemented on a widescale could streamline the audit process and compel each party in the supply chain to employ best practices.

Robots Streamline Production Processes… To an Extent

So, we have heard all about the benefits of technology in the supply chain, but what are the drawbacks? Well, firstly, advanced technology that can really transform productivity are still extremely expensive, meaning many supply chain companies remain reluctant to adopt them.

That being said, in the long term, these high outlays can pay off. A BCG analysis found that using advanced robots in combination with other technologies, process enhancements, and structural layout changes can generate savings of up to 40%.

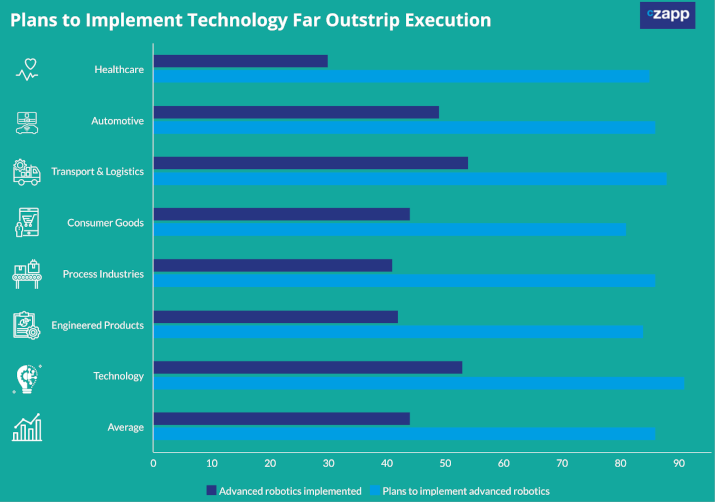

And there is still relatively low penetration of robots, with automation achievements regularly falling short of ambitions.

Source: BCG

BCG also found that the size and location of a company affects robotics adoption. Companies in the Americas have been much slower adopters than those in Asian countries, for example. And among small businesses, level of adoption in constrained by budgets.

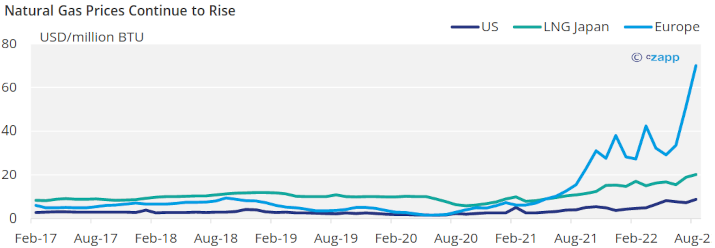

High energy costs could also constrain the adoption of automation in the coming years, given the higher energy requirements of machines. Due to the Russian invasion of Ukraine, energy costs are skyrocketing around the world due to rising gas prices.

Concluding Thoughts

But can robots really replace humans? The short answer is probably not. While robots have their advantages, they cannot compete with a human brain and its ability to process, make decisions and problem solve. Essentially, humans always have to be there to tell a robot exactly how and what to think.

For employers, these skills are important. A 2017 survey carried out by Nesta on The Future of Skills shows that interpersonal skills are in high demand. For the US, social perceptiveness, originality and judgement and decision making were all ranked highly. These are all skills a computer is incapable of developing – at least for now.

So, while robots and technology can be used smartly by companies to mitigate challenges and streamline processes, this does not mean that humans will be obsolete as more humans will be required to service machines. There is also no substitute for human ingenuity, which will be more in demand as technology advances.

In short, machines aren’t here to take our jobs, but the most in-demand skillsets will certainly change.

.

.

Related Content:

Will 2022 Be the Summer of Port Congestion?