Insight Focus

- Sustainability in packaging is no longer optional – it is essential for survival.

- But how can F&B companies integrate sustainability without a huge supply chain overhaul?

- Here are some fast solutions that don’t need to disrupt operations.

Sustainability Leads to Profitability

Sustainability is a major driving force in the global packaging industry, with brands across the FMCG sector keen to respond to consumer demand for more responsible packaging solutions. Legislation is a dramatic influencer too, as while the consumers vote with their feet, the law uses a sharper tool, although both have a considerable financial impact.

Brands want to be sustainable anyway, so this is not an empty trend driven only by legislation. Companies need to appeal to environmentally educated young people to continue to grow, and existing employees want to protect their careers and work in a business they are proud to be part of.

For the plastic packaging industry that serves the enormous food and beverage industries, choosing sustainable packaging is increasingly less about choice and more about survival, whether that squeeze is coming from consumers choosing sustainable alternatives or from regulatory changes that push towards more responsible solutions.

A Win-Win Situation

So, what quick wins can brands choose to help move their packaging options in the right direction, without having to introduce costly or impractical answers that tick the regulatory box but not the commercial sense box.

Emmanuel Duffaut, Chief Sustainability Officer at plastic packaging producer RETAL, is a vocal advocate for the circular economy, believing that when plastic packaging is done right, it is the most sustainable choice for much of the food and beverage industry.

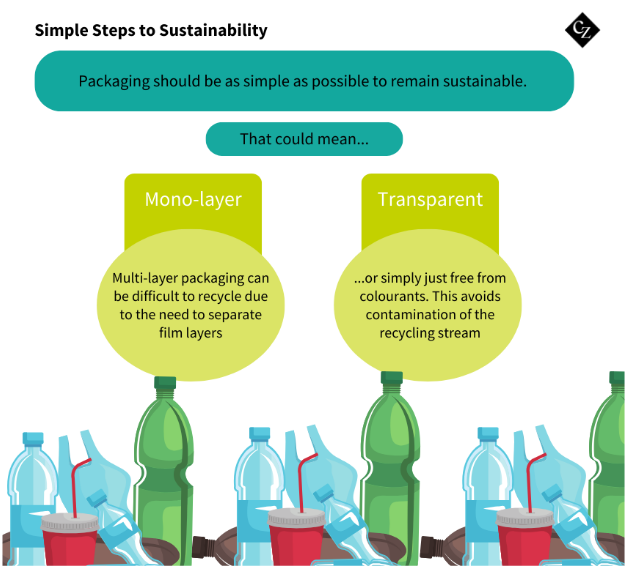

“An easy, quick decision is to make sure nothing in your packaging hinders recycling. So mono packaging materials rather than multi-layer, as these are far harder to recycle, unless the packaging specifically has been developed to be recycled,” says Duffaut. “For PET bottles, this means that whatever virgin PET or recycled PET that was used in the production of the preforms can be effectively collected and easily segregated for recycling after use.”

Colourants a No-Go

Another way to support easy recycling within the current infrastructure is for brands to reduce and ideally refuse use of additives or colourants in their PET packaging, which is the most popular type of packaging for the FMCG market.

By encouraging transparent or just barely coloured plastic packaging, companies can create far more value in the recycling stream. This is because the additives and colourants can alter the recycled content and either discolour it (at best) or reduce its properties (at worst), making the collected used PET unusable and therefor a wasted virgin resource.

We see this move away from additives and colourants on our supermarket shelves as global beverage brands want to highlight their sustainability credentials and show to an increasingly environmentally conscious consumer base that they can have the products they want without costing the earth.

“Choosing recyclable packaging is an easy decision as large plastic packaging producers like RETAL are able to guarantee a reliable supply of recyclable PET and/or up to 100% rPET (recycled PET) preforms,” Duffaut says. “We mustn’t forget that PET packaging is lightweight, easy to transport, practically unbreakable, reusable, takes far fewer resources to recycle that other packaging materials, and is easy to form into eye-catching shapes and designs.

“Plastic can look after us if we look after plastic.”