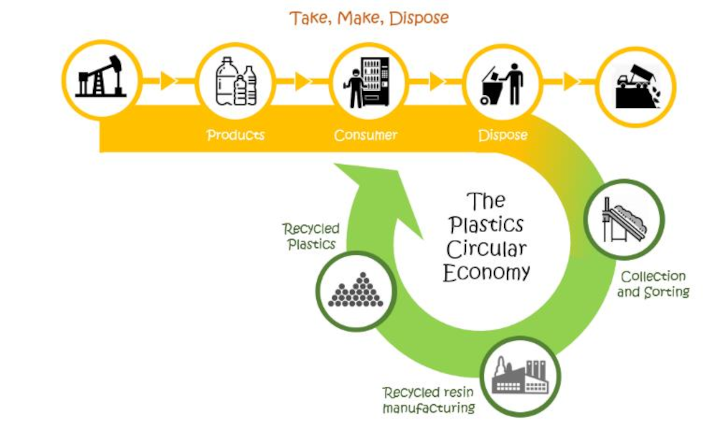

What is the Circular Economy?

- The circular economy looks beyond the current “Take, Make, Dispose” linear consumption pattern.

- Changing to a circular model helps reduce waste and pollution, whilst keeping products and materials in use.

- A circular approach also helps decouple plastics manufacturing from the consumption of petroleum-based resources.

Key Stages in Recycling PET

1. Collection: mechanisms range from curbside collection to deposit return schemes. Return schemes result in the highest quality of material.

2. Sorting & Baling: Curbside collection typically requires additional sorting at a municipal recycling facility (MRF). Waste is separated by material type and polymer. Bottles are then baled and traded globally.

3. Grinding & Washing: Plastics are shredded into smaller pieces. Hot and cold washing removes contaminants and improves PET flake quality.

4. Flakes & Pellets: Plastics are finally converted into new plastic products, including flakes and pellets.

5. End-Use Applications*: RPET flakes and pellets can be used in the production of end-use products similar to virgin plastic.

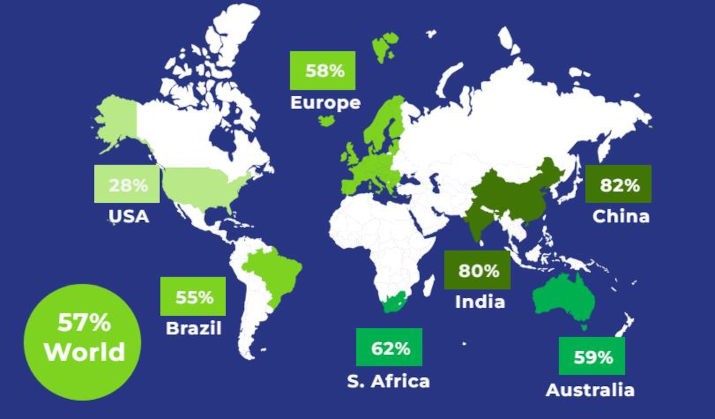

* Percentages estimated on a global basis

PET Bottle Collection Rates Across the Globe

One of the limiting factors in the availability of RPET material is bottle collection.

Bottle collection varies between countries and regions.

Those with established bottle return schemes tend to have the highest collection, e.g. Germany with a rate of ~95%.

This Czapp Explainer was Published on the 29th June 2021.

For information on PET Resin and Plastic Packaging, please contact GLamb@czarnikow.com.