Insight Focus

- We have visited the San Diego Trinidad mill in Guatemala.

- The mill is located close to Puerto Quetzal on the Pacific Coast.

- Read on for information and photos.

Travelling to the Mill

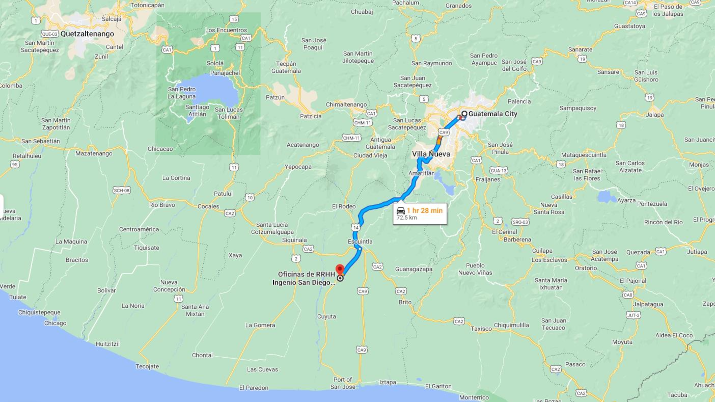

Stephanie Rodriguez and I started early to beat the morning traffic. At 5:30 am we were on the road for the 90km trip from the city to the coast. With clear roads it takes around 90 minutes. With heavy traffic this can easily become 3h.

We were travelling to the San Diego Trinidad sugar cane mill. It’s located near the Pacific coast and has been producing sugar from cane for more than 130 years. It was acquired by San Diego group in 1987, partly due to its location just 35km from Guatemala’s major sugar export port, Puerto Quetzal. This proximity allows for easy truck transportation to the port.

From the mill entrance, you can see the Acatenango Volcano (far left in picture), the Fire Volcano (middle), and the Water Volcano (right; Guatemala largest volcano). I once climbed the Acatenango Volcano. It was a gruelling 14-hour hike, but the view at the top makes the climb worth it.

San Diego group grows around 44k acres of cane in the area near Trinidad mill. This cane is trucked to the mill during the harvest season, which has just started.

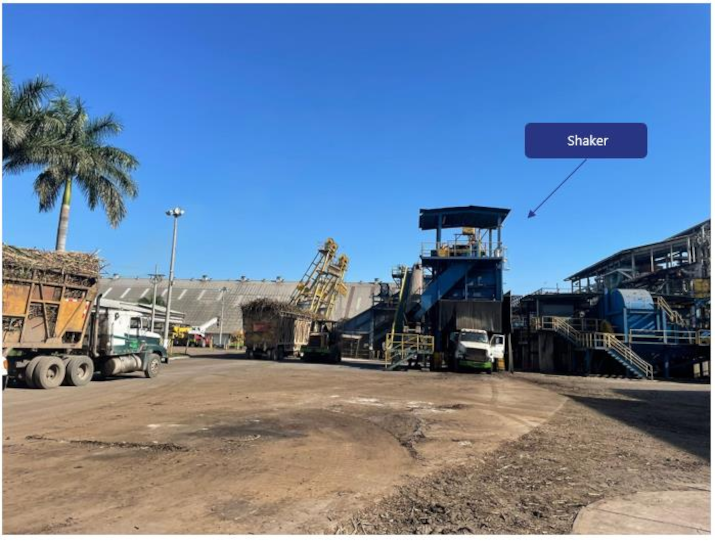

Upon arrival the cane trucks are weighed, the cane is unloaded and the empty trucks are weighed again so that the exact tonnage of cane delivered can be calculated.

Once the cane is unloaded it’s put into a shaker, which separates the cane from weeds and other waste.

We had a slightly easier entrance to the mill: we were given a safety briefing, hard hats, safety glasses, ear plugs and steel toe protection before being allowed on site. The mill employs around 5,000 people.

Here we are at the workstation which manages the cane shakers.

The cane is then crushed by the mill and the cane juice (rich in sucrose) is extracted. The juice is then concentrated, cleaned and crystallised to make raw sugar. The leftover cane fibre is dried and compressed to form bagasse, which is used as a fuel for the mill boilers. Here I am watching the cane bagasse being burned.

Some of the raw sugar can be further processed into refined sugar. The Trinidad mill’s output is roughly 60% raw sugar and 40% refined.

After it’s been made, the sugar is stored on site in warehouses before being moved to port for export or inland for domestic consumption. Refined sugar is food-grade and so is stored in bags.

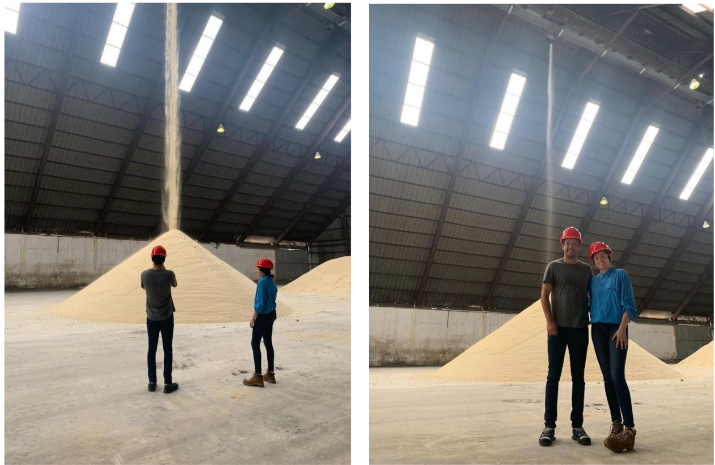

Raw sugar is an industrial product which requires further processing before being safe for human consumption. Its handling requirements are therefore less stringent. It’s moved into the warehouse by conveyer.

It’s then stored directly in the warehouse.

Today the raw sugar warehouse is mostly empty as it’s the start of the cane crushing season and raw sugar is already being moved to Puerto Quetzal for export. But over the coming weeks the warehouses will continue to fill. Cane crushing and sugar production doesn’t stop while the harvest is underway.

Finally, on our way back to the city we stopped for the Guatemalan delicacy of Pollo Campero to re-fuel.